Small manufacturers have to balance a web of interlinked processes, from the management of inventory and production schedules to coordination with suppliers. All these processes require perfect accuracy and speed, leaving little room for error or inefficiency. This can quickly become very overwhelming for any organisation operating on the basis of disconnected systems or manual management systems, leading to bottlenecks, miscommunication, and waste.

An ERP system consolidates these functions into one framework, offering a centralised platform that brings clarity and structure to operations. Below we explore five benefits ERP software brings to manufacturers.

1. Streamlined Processes for Maximum Efficiency

Businesses often have to overcome problems created by fragmented systems, manual workflows, and inefficiency that slows down productivity. ERP solutions resolve these issues by standardising operations and automating mundane tasks, such as order processing, tracking inventory, and financial reconciliation. Since the ERP platforms integrate data across different departments, the platforms eliminate redundancy and enhance data consistency. Streamlining saves time and frees the employees from such trifling to invest this time in a more essential activity.

Picture a manufacturer who has to handle hundreds of SKUs. In this case, an ERP system would sync the stock levels with supplier lead times automatically to avoid overstocking or shortages. That saves the company from delays, advances its production on schedule, and increases the overall efficiency. In this way, efficiency becomes so achievable that it is no longer a goal, but rather the standard.

2. Real-Time Insights Drive Smarter Decisions

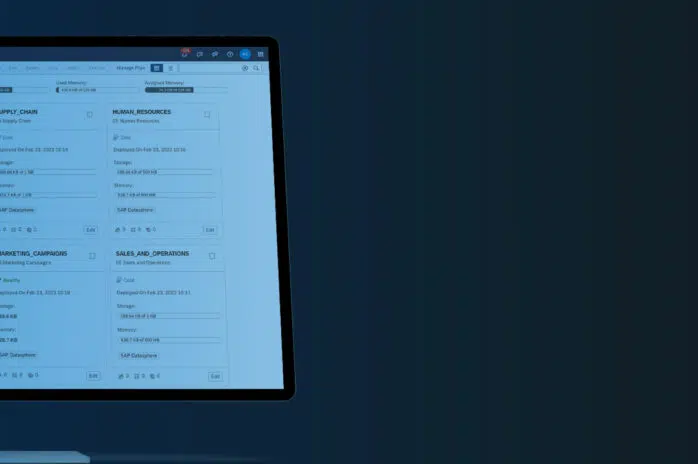

While informed decision-making requires up-to-date and timely information, many legacy systems are based on delayed or static reporting, which leaves gaps in visibility. Such limitations are overcome by ERP systems, which consolidate data from multiple sources into centralised dashboards and offer real-time analytics on anything from production performance to customer trends.

For example, an organisation might want to understand better the usage of equipment or its most valuable customers. This information becomes available through ERP software and helps in giving a really detailed insight into operations by revealing certain inefficiencies and areas of opportunity. Leaders can decide on changes in strategy with a high degree of precision in either short-term adjustment or for long-term decisions.

3. Scalability and Adaptability Support Business Growth

As with any company’s growth, the demands of manufacturing companies grow with their operations. A non-scalable system quickly leads to inefficiency and overload, which in turn slows down the pace at which manufacturers can adapt to new challenges. ERP platforms are built to scale with businesses and absorb additional workloads-such as more product lines, or geographic expansions-without requiring a complete overhaul. These platforms ensure that the systems are always functional and efficient at any stage of growth.

This might mean that a small business initially implements the basic modules for inventory and production and then, perhaps after some time, adds CRM or other analytical tools as their needs evolve. In this manner, modularity ensures the system grows along with the company by continuing to support changing objectives and operations. With the flexibility to expand and adjust, businesses can maintain smooth operations and respond to market shifts without disrupting their core processes.

4. Improved Compliance and Traceability

For manufacturers, conformity to industry regulations is at the heart of operational integrity and stakeholder trust. This is even more critical in sectors where the standards for safety, manufacturing environment, or quality are high and where the potential consequences of non-compliance are serious, from highly expensive fines to reputational damage. ERP systems automate many of these tasks in an attempt to address compliance challenges. They ease the auditing process, keep records of each transaction, and generate the reports that are needed to meet the demands of regulatory requirements.

This ranges from industries like food productions, pharmaceuticals, to even the chemical industries, for which traceability is just non-negotiable, to name a few areas where ERP provides unparalleled supply chain visibility. From raw material procurement to finished goods shipped, the ERP platform extends real-time visibility into the various stages of production continuously. This keeps track of materials and products efficiently, noting each detail accurately for immediate access when needed.

ERP systems help manufacturers comply with increasing regulations and offer full traceability. This not only minimises regulatory violation risks, but also helps foster greater trust with partners, customers, and regulators by demonstrating a commitment to quality, safety, and transparency throughout the supply chain.

5. Enhanced Customer Satisfaction Through Better Service

Customer expectations keep rising, and businesses need to keep up with these growing demands. For manufacturers, this means delivering reliable, accurate, and efficient service to maintain customer loyalty. ERP systems play a key role in meeting these expectations by streamlining order fulfilment, managing inventory accurately, and ensuring on-time deliveries. Integrated CRM tools take this a step further by enabling personalised communication and responsive customer support.

Whether it is large, complex orders or many small shipments, businesses that have an ERP solution in place can offer a consistent and reliable service. Customers like quicker delivery and fewer errors, with clear communication, strengthening relationships and encouraging repeat business.

Why ERP Systems Are a Game-Changer

Besides solving operational problems, ERP solutions provide the structural basis for growth: fewer errors, more agility, and effective deployment of resources. Their ability to centralise processes across production, sales, and finance makes them indispensable in manufacturers’ eyes for scaling without losing quality or profitability.

Codestone specialises in the implementation of ERP solutions that are designed to meet the needs of small and medium-sized manufacturers. With broad experience in providing top of the line SAP, Microsoft and cloud IT services, Codestone makes the move towards a scalable, future-proof ERP ecosystem seamless. Through close collaboration with your team, taking the time to understand your objectives, and providing a customised implementation process, Codestone will make sure that the adoption is smooth and the operational benefits are immediate.

Take the first step towards efficiency and growth. Reach out to us today to discover how ERP can transform your manufacturing operation.