The wholesale distribution industry has reached a real fork in the road. What was once considered standard business practice no longer works for a market driven by digitisation. With increasing competition, shifting customer expectations, and increasingly intricate supply chains, wholesale distributors will need to adapt much faster – or risk becoming obsolete. Rather than merely adding new tools, this process is one of forging a new core with the use of ERP or Enterprise Resource Planning systems, for example. An ERP system, instead of being another new solution involving software, may better be described as an active promoter of renovation and expansion that actually gives distributors the keys for change in and leadership within the more digital market.

In this post, we will explore the challenges faced by distributors, the true cost of standing still, and how ERP systems can act as a strategic lifeline.

The Evolving Wholesale Landscape

Wholesale distribution has changed considerably. From being a place of focus on bulk orders and simple logistics, today, the industry has transformed to encompass new and unparalleled complexities. Additionally, the rules have been rewritten by the e-commerce giants, who have made speed, transparency, and precision paramount.

An increasingly complex global supply web exacerbates this challenge. From pandemic-induced supply bottlenecks to geopolitical ambiguities, the pressure on distributors to continually readjust their operations is unrelenting. The competition is coming not just from other wholesalers but also from retailers, direct-to-consumer brands, and lower-overhead startups increasingly competing against distributors with their digital proficiency to outmanoeuver slower competitors.

In all these ways, for a wholesale distributor, challenges are not just operational; they are existential. Outsiders appear so much more fleet-footed against the competitive backdrop brought about by technological savvy. In that light, a robust and connected digital backbone has never been more important.

The Challenges Defining Today’s Industry

Wholesale distribution has never been easy, but today’s environment is particularly unforgiving. The pressure brought about by the emergence of e-commerce has pushed traditional business models to their limits, forcing distributors to rethink everything from how they manage inventory to how they engage customers. Online giants have increased the demand for operational excellence, real-time responsiveness, and innovation.

Additionally, organisations must manage complexity like sourcing materials, maintaining inventory across a number of locations, and managing deliveries-while preparing for and responding to unexpected disruptions-all feel like a balancing act. Customers have never been more demanding, requiring precise and timely information relative to product availability, price, and delivery schedule and leaving little room for error.

Labour shortages only exacerbate these issues: finding skilled staff and keeping them is becoming increasingly difficult, and increasing reliance on technology in an effort to bridge the gap is patently inadequate. Together, these challenges create a climate in which clinging to the old ways isn’t just impossibly impractical but actually unsustainable.

The Cost of Doing Nothing

It’s tempting to stick with the status quo, delay big decisions, and hope the challenges blow over. Inaction has a very expensive price tag. Distributors that resist modernisation risk being left behind by competitors who are faster, more efficient, and better equipped. Market share dwindles, operational inefficiencies compound and customer dissatisfaction takes hold.

Lost customers aren’t all that’s at stake. Employee morale suffers when archaic systems make their jobs more difficult than they should be. The efficient staff move elsewhere for opportunities, leaving the business in an even weaker position. This leads to the loss of opportunities, such as a new market, lucrative partnership, or innovative product line.

How Wholesale Distribution ERP is an Industry Gamechanger

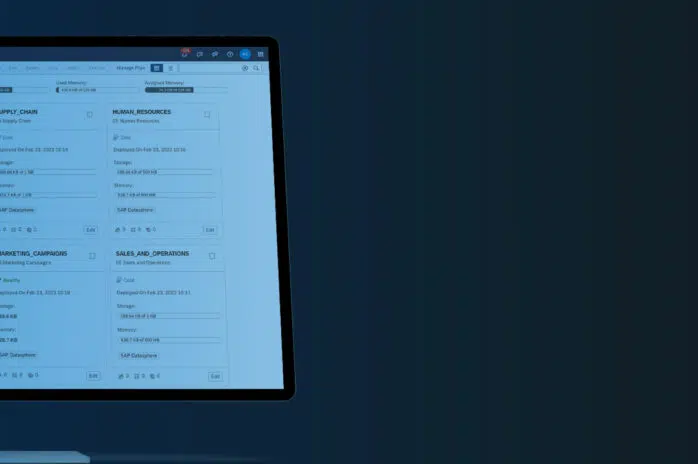

For many, the answer comes in the form of ERP. These systems address industry challenges with integrated operations and the type of visibility that fosters transformative change.

Take Totally Wicked, a UK vaping distributor, for example. Before its adoption of Cloud ERP, inefficiencies in procurement, inventory, and financial reporting restricted growth. Supply chain automation, including automation of processes, centralisation of data, cost reduction, and so on-the new system finally paved the way for such sustainable success.

Similarly, TS Catapult, a technology distributor, used Cloud ERP to bring together fragmented systems, enabling smarter decisions, streamlined operations, and stronger customer relationships.

Wholesale distribution ERP systems help supply chains become more accurate by offering full visibility, automating error-prone tasks, and freeing employees for higher-value work. Advanced analytics power smarter decisions, while faster response times and personalised services boost customer satisfaction.

Unlocking Competitive Advantages

The benefits of ERP for wholesalers are as varied as they are powerful. Inventory management is now a science rather than a guessing game. Inventory control solutions use predictive analytics to ensure that the stock levels are optimised to reduce both stockouts and overstocking. Order accuracy improves dramatically, thanks to automated workflows that leave little room for error.

ERP systems are great at managing cash flow, automating financial operations, and providing unrivalled visibility into the revenue cycle. Additionally, an ERP with a good warehouse management system helps businesses optimise resources and gives them the ability to provide faster and more reliable services, improving customer satisfaction. Most importantly, ERP offers a competitive advantage that’s critical to success in today’s market.

Keys to Successful Implementation

Not all ERP projects succeed. The difference often comes down to preparation and execution. This process hinges on several critical factors:

- Strategic planning ensures that the system aligns with business goals and addresses specific challenges.

- Change management helps organisations navigate the cultural and procedural shifts that come with new technology.

- Staff training is essential to empower employees to make the most of the system’s capabilities.

- System selection involves choosing a platform that fits the unique needs of the business, with scalability for future growth.

- Timeline management keeps the project on track, avoiding delays and cost overruns.

The ROI of ERP

A good ERP investment lays the path for the success of your organisation by increasing your distribution business efficiency. These solutions reduce costs, decrease errors, and save time by simplifying business processes and enabling employees to be more productive. Customers are happier when distributors consistently meet or exceed expectations, which leads to stronger customer retention and opens the door to new revenue opportunities. Additionally, ERP systems enable market expansion by providing the tools needed to enter new regions or sectors with confidence.

Modernisation starts with assessing your ERP readiness. Whether you’re implementing a new system or optimising an existing one, Codestone can help. Check out our website to see how ERP can transform your business, or schedule an ERP Health Check to ensure your current system delivers maximum value.