In the dynamic and competitive manufacturing industry, the pressure to innovate, streamline, and outcompete is constant. It takes more than simple cost-cutting or sustaining production flow to stay ahead, it requires agility, insight, and control to turn challenges into opportunities. And that is where a modern Enterprise Resource Planning system can become a game-changer. ERP transforms how businesses operate, from the complexity of process to seamless efficiency, unleashing the potential at every stage of manufacturing.

In this article, we look at the transformative power of ERP for manufacturing and why it is so important to align with the right ERP partner to maintain growth.

The Complexity and Challenges of Manufacturing

Manufacturing operations are pretty complex in nature. Right from procurement and production to logistics, customer delivery requires perfect coordination. Some of the external factors that add to the complication include global competition, fast fluctuating raw material prices, disrupted supply chains, and ever-increasing expectations of customers on quality customised products.

Add to that regulatory requirements, sustainability goals, and the increasing complexity of cybersecurity threats, and manufacturers have their hands full. Conventional, fragmented systems can’t provide the speed and visibility necessary to rise above these challenges and leave companies exposed to inefficiency and missed opportunity.

How ERP Solutions Meet Manufacturing Needs

ERP systems alleviate these problems by uniting fragmented functions into a cohesive platform. It enables seamless communications across the board and gives visibility into operations in near real time. To a manufacturer, it presents tremendous benefits through every stage of the production cycle.

An ERP system smoothes out supply chain management by providing accurate demand forecasting, maintaining relationships with suppliers, and minimising stockout and overstock situations. This ensures resources are utilised efficiently, saving money and time.

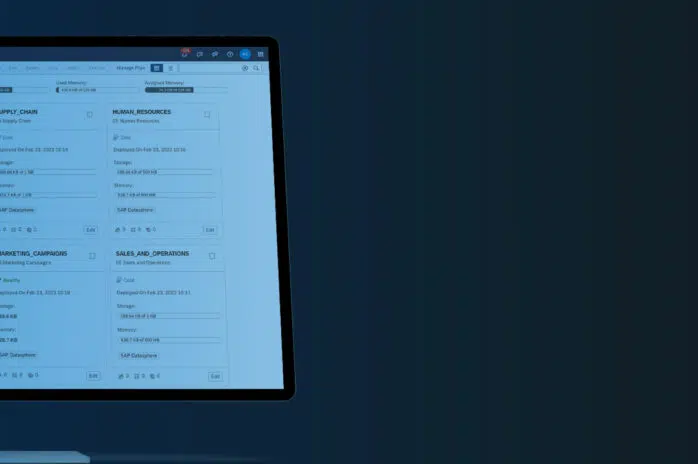

Additionally, ERP delivers a wide overview of the shop floor in production planning, making exact scheduling, resource allocation, and monitoring possible. It is through these insights that manufacturers are able to view bottlenecks, measure performance, and effect necessary corrective actions.

With ERP, huge amounts of operational data are transformed into actionable insight to drive data-driven decisions, setting manufacturers on course for anticipating customer demand, enhancing plant utilisation, and addressing inefficiencies before they can affect the manufacturing process.

Other areas in which ERP systems make manufacturing easy include regulatory compliance and quality management. With ERPs automating checks, documentation of compliance efforts, and maintaining quality standards, a manufacturer is able to remain compliant with little or no dependence on human resources.

ERP systems also enhance customer experience through integrated CRM capabilities, which help manufacturers respond to client needs with greater accuracy and speed, nurturing better relationships and improving satisfaction.

The Shift to Cloud ERP

The transition from on-premise ERP to cloud-based solutions created a shift in the manufacturing sector. Cloud ERP provides incomparable scalability, flexibility, and cost-efficiency. Cloud-based solutions are also able to grow as the business expands, accommodating added data, users, and functionalities without needing heavy infrastructural upgrades.

Cloud ERP systems also offer a remote accessibility feature that enables the team to monitor operations and collaborate from anywhere, which is especially valuable in the context of managing global supply chains, where round-the-clock oversight is required. Security is another advantage, as cloud providers often implement advanced safeguards that surpass the capabilities of in-house IT teams.

A Strategic Investment

Despite the obvious advantages, implementing or upgrading an ERP system can be daunting. Concerns about cost, downtime, and user adoption are justifiable, but the long-term benefits far outweigh these issues. Investing in ERP ultimately enables manufacturers to scale effectively, innovate quickly, and remain competitive in a vibrant market.

The selection of an appropriate ERP provider is the first step toward a successful implementation. Manufacturers need a partner who can understand their particular problems and provide solutions tailored to their needs.

The Importance of Selecting the Right ERP Provider

Most manufacturers begin with an ERP provider that fits their needs at that moment. But businesses grow and evolve, they often outpace their provider’s capabilities. Indicators of this misalignment include outdated software, sluggish responses, and a lack of proactive recommendations and insightful sector-based views. The optimal ERP provider does not stop at providing technical support, it provides a strategic partnership that includes driving innovation through the alignment of ERP systems to longer-term goals. An ERP system should be a tool for seamless operations and strategic decision-making, not a source of frustration or inefficiency.

Recognising when it’s time to upgrade or switch providers is critical. Signs of an inadequate system include slow performance, limited scalability, frequent user frustrations, or a lack of proactive support from your provider. A modern ERP system evolves alongside your business, incorporating new technologies, addressing industry-specific challenges, and providing innovative solutions to stay ahead of the competition.

Why ERP Evolution Matters

ERP is not a static tool, it is a dynamic system that grows with your business. Adding third-party integrations, building out capabilities, and testing new features are part of maintaining a system to meet evolving needs. A provider that fails to proactively suggest improvements or optimise your ERP solution can hold your business back.

Switching to a more capable ERP provider is not just about fixing current issues. It’s about building a partnership that supports long-term goals, from implementing cloud-based solutions to ensuring seamless day-to-day operations. A reliable provider understands your industry, anticipates challenges, and works alongside your team to drive growth and innovation.

Partnering With Codestone for ERP Success

In order for manufacturers to realise the full benefit of an ERP system, they require a trusted partner to help them through the process. Codestone specialises in the design and implementation of tailored ERP solutions, which transform the way manufacturers operate. With extensive and diverse experience in a wide range of industries, Codestone has the experience and expertise to install an ERP system that meets all your business objectives.

Contact us today and find out how an ERP solution can transform your manufacturing operations. Whether that is a move to the cloud or the continued enhancement of your system, Codestone will ensure your ERP evolves with your business.